Multi-deep Shuttle ASRS

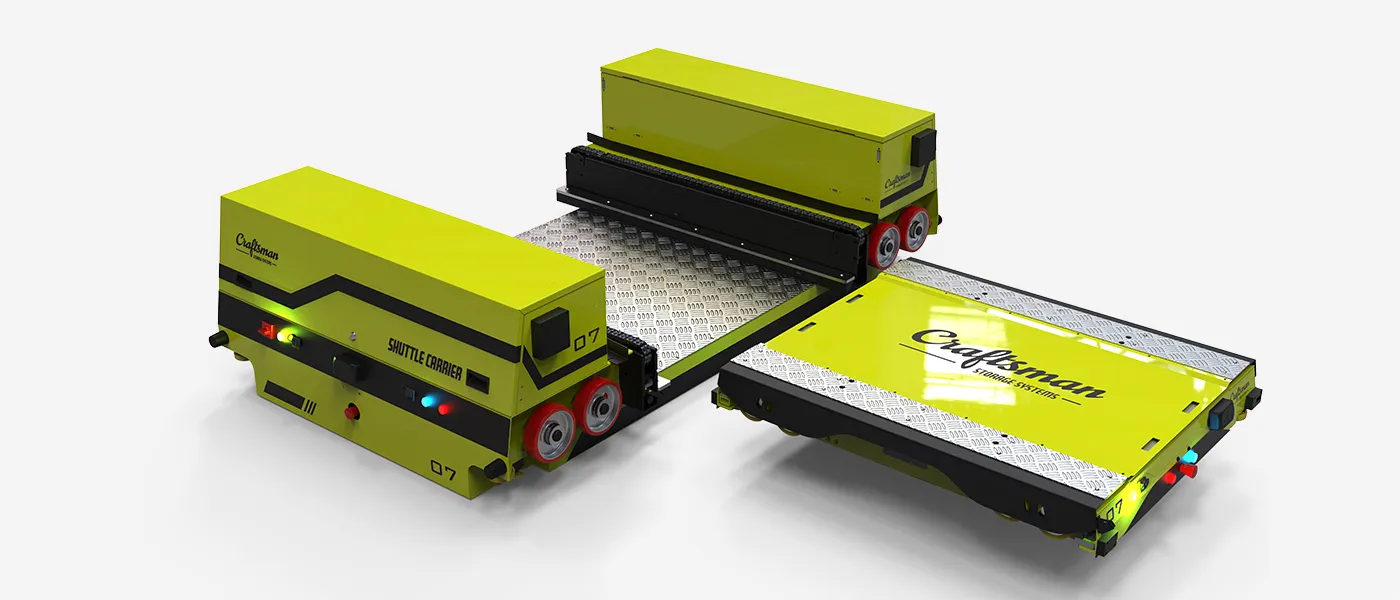

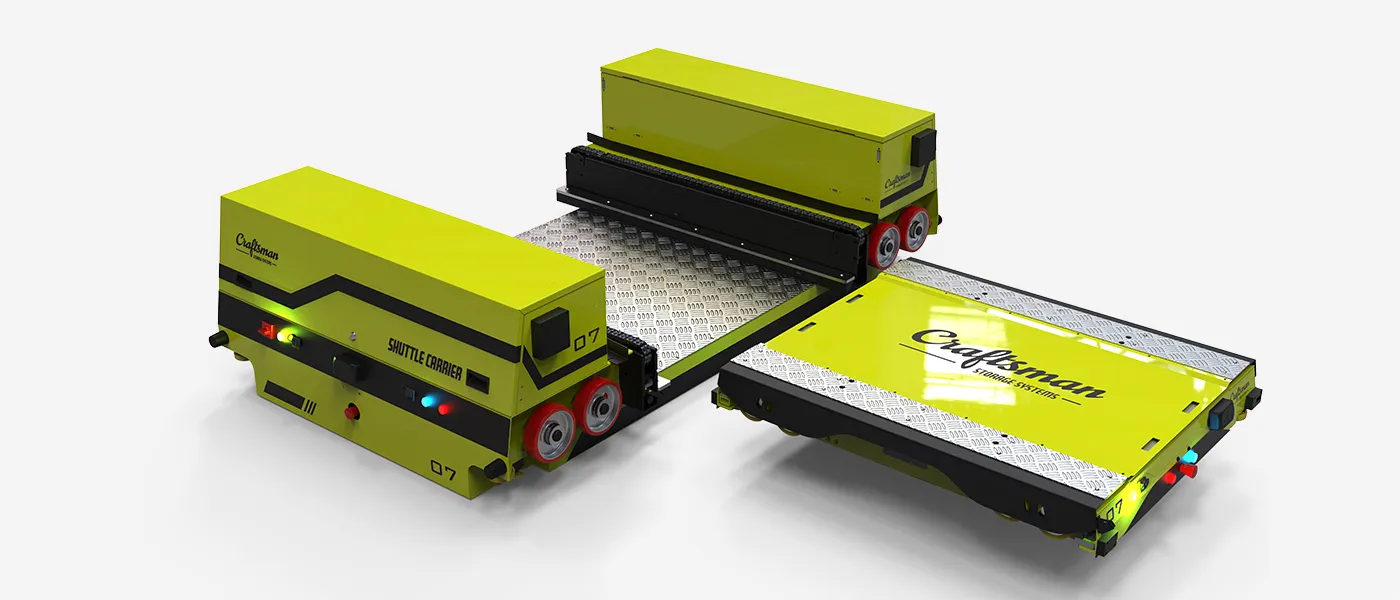

Multi Deep Shuttle ASRS offers an automated storage solution to deliver and stack the products between the different pallet levels. Craftsman’s Shuttle ASRS is an integral and holistic operation of different equipment in a tandem.

- Ultra-capacitor-powered pallet shuttle

- Shuttle-carrier

- Pallet lifter

- Buffer conveyors

Pallet ASRS Crane

Automated storage and retrieval machines that run on rails, with a single or double mast frame depending on the requirements of the system. Equipped with telescopic forks, for the storage and retrieval of pallets from single or double-deep racks, making this solution is highly adaptable to a wide range of materials and handling needs.

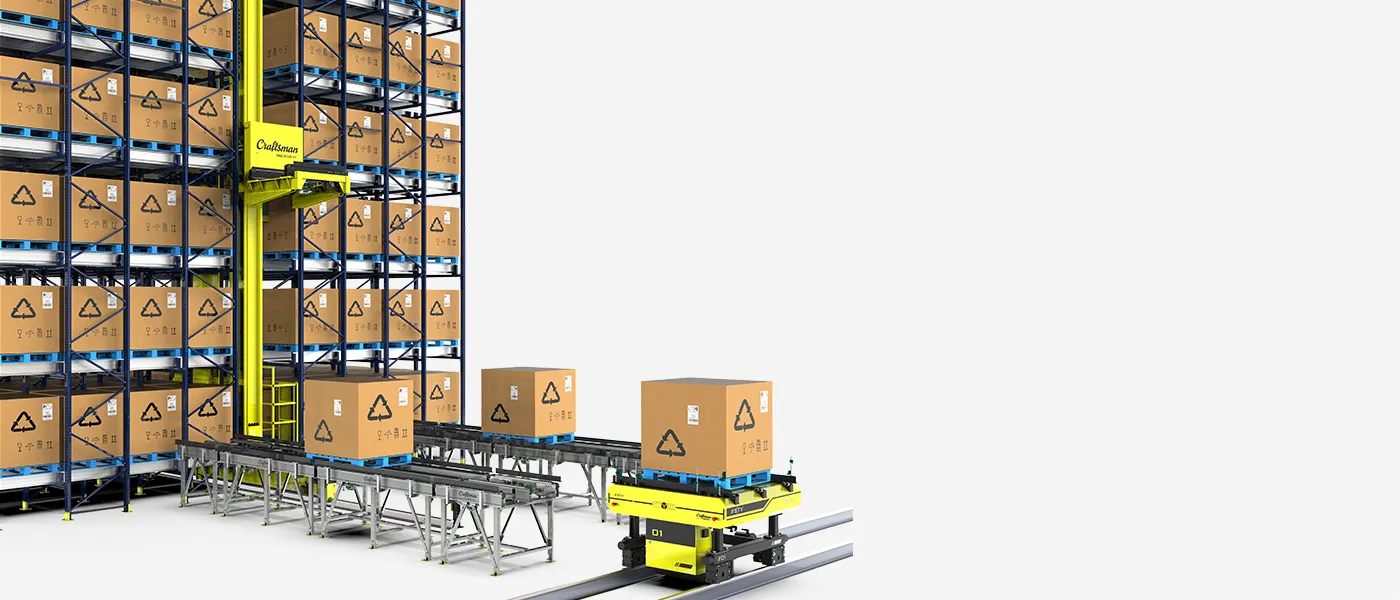

Crane Shuttle ASRS

Our Pallet shuttle systems are incorporated with Stacker Cranes for higher density storage racking. The stacker crane carries out movements from input and output locations to the storage channel replacing forklifts for faster and more efficient material flow.

Pallet conveyors Systems

Warehouse operations require a steady flow of materials for production, storage, and dispatch purposes. Every material has diverse features and requires conveyor systems that service handling and distribution within the facility. We at Craftsman design flexible and cost-effective pallet conveyor systems suitable for assembly lines or storage facilities, using automatic or manually controlled workstations thereby increasing productivity and reducing costs.

Sorting and Transfer Vehicle

The STV system is based on intelligent, high-speed, and rail-guided vehicles customized for specific load-handling applications. This technology is an efficient, cost-effective, and fast option for complex sorting applications or connecting very distant points. It is also an interesting alternative to long conveyor lines and reduces queuing.

Multi-deep Shuttle ASRS

Multi Deep Shuttle ASRS offers an automated storage solution to deliver and stack the products between the different pallet levels. Craftsman’s Shuttle ASRS is an integral and holistic operation of different equipment in a tandem.

- Ultra-capacitor-powered pallet shuttle

- Shuttle-carrier

- Pallet lifter

- Buffer conveyors

Craftsman’s Warehouse management system is made to help users improve the efficiency of tracking inventory and supplies in a storage system. Through our WMS various processes like Picking, Sorting, Transfer are made possible. The WMS can be a stand-alone service or it can be integrated with an Enterprise resource planning (ERP) or Supply Chain Management (SCM) software, thereby significantly enhancing user experience. Advanced reporting features within the software helps managers analyse performance of the operation as a whole and find areas of improvement. The WMS software designed inhouse is customer specific i.e. configurable to the users needs, rather than requiring you to change your business to fit the software.

WMS System helps to manage a Warehouse like a Conductor of an Orchestra by

- Synchronizing all warehousing activities starting from Receiving up to Dispatch & Truck Loading.

- It leverages advanced data capture using Barcode labelling / RFID tagging and related technologies.

- Helps to Synchronize activities towards phased prioritized picking through Wave Management

- Can trigger extensive Alerts for operators, for required manual actions/interventions.

- Leads to a Robust & Load balancing system, every-step-of-the-way.

With a well-integrated WMS System

- Helps to provide visibility of inventory of Goods through-out the entire Warehouse life cycle.

- Supports in significantly reducing the operating cost by shortening order-fulfilment cycles.

- Reduces inventory costs implementing MOQ and automated replenishment.

- Boosts productivity by using Task Interleaving features for high throughput.

- Improves inventory accuracy.